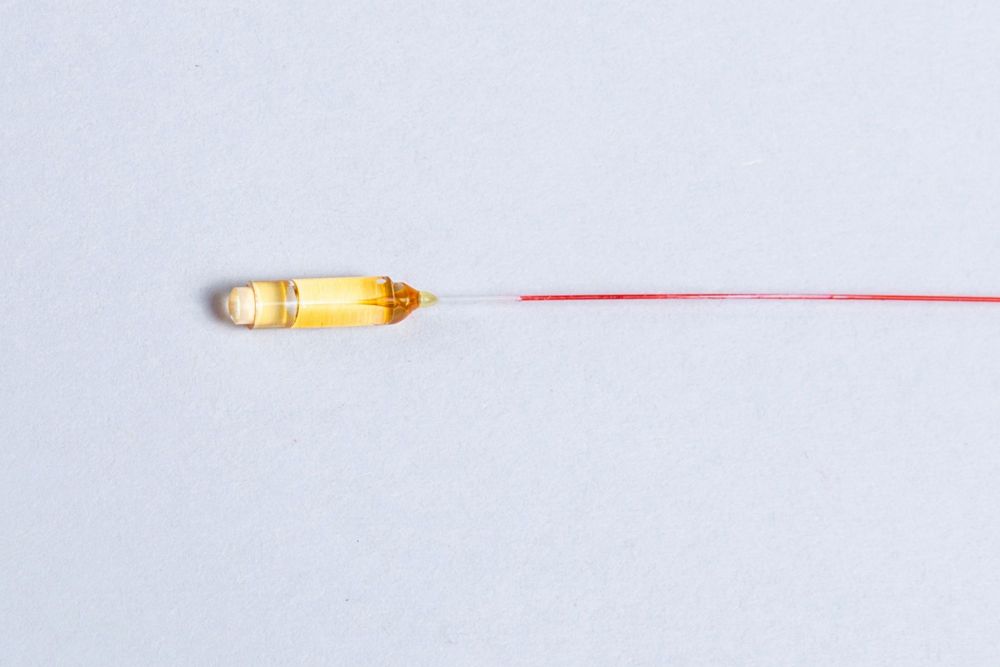

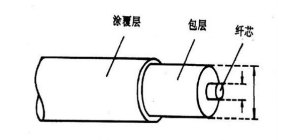

Conventional fiber is composed of three parts: core, cladding and coating. As shown in the picture the fiber core completes the transmission of the optical signal. The refractive index of the cladding and the core is different, which can enclose the optical signal in the core for transmission and protect the core. The main function of the coating layer is to protect the fiber from the outside world. damage, while increasing the flexibility of the fiber. Because both the core and the cladding are made of glass, which is fragile when bent, the use of the coating layer protects and prolongs the life of the fiber.

When using the fusion taper process to make optical fiber couplers, the coating layer on the surface of the optical fiber needs to be stripped and cleaned. In order to make high-performance optical fiber couplers, it is necessary to ensure that the coating layer is not worn when stripping the coating layer.

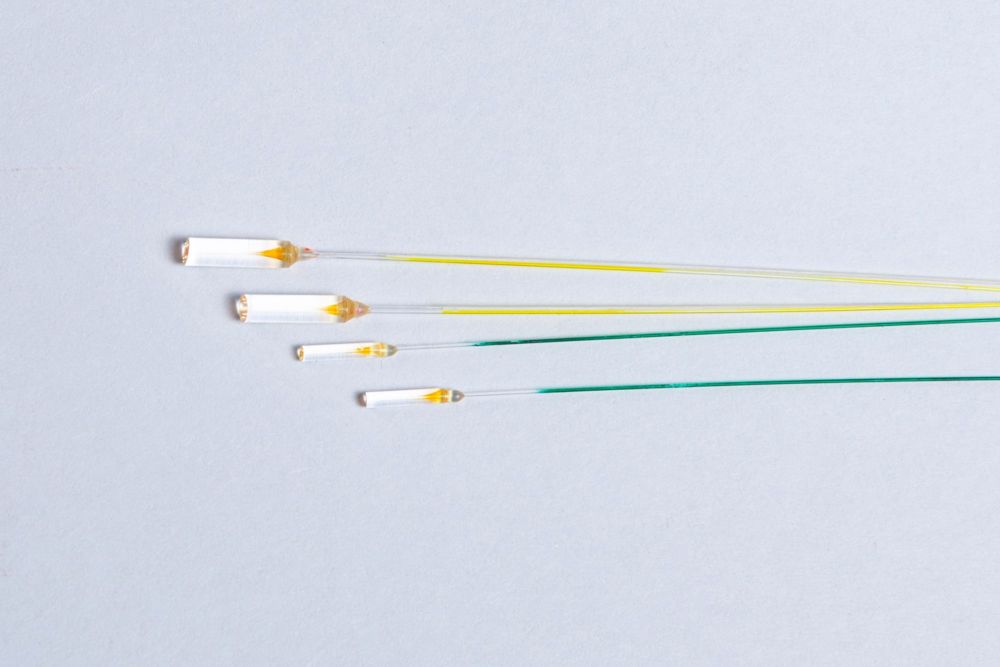

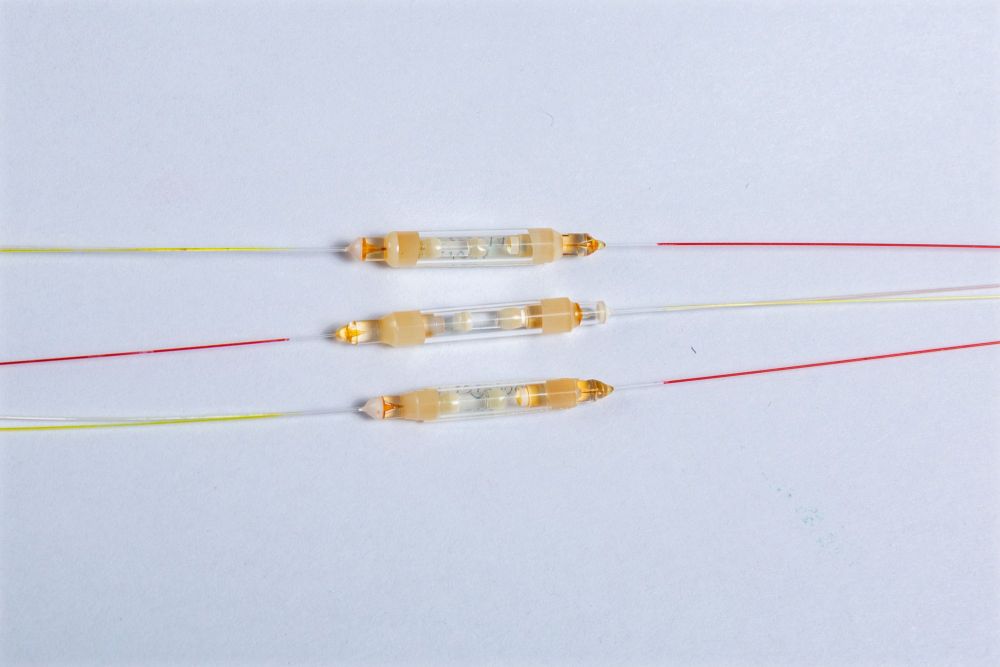

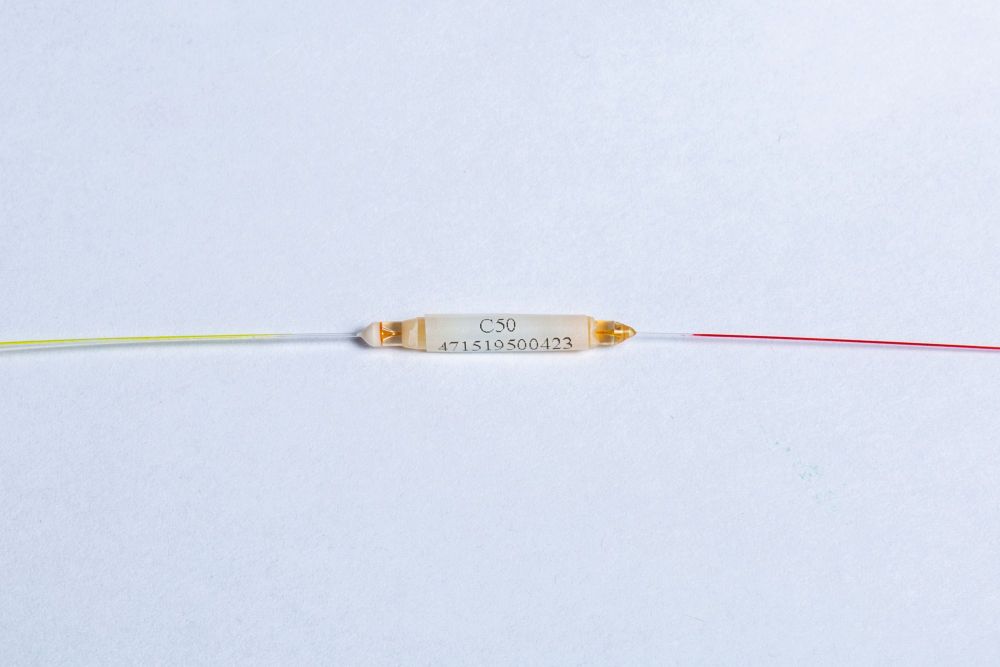

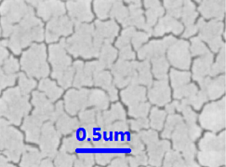

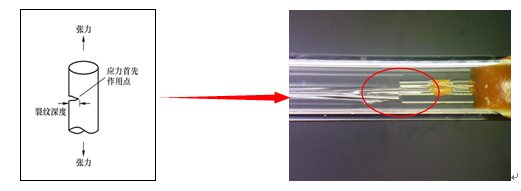

One of the typical failure modes of fiber optic couplers is that the micro-cracks on the surface of the fiber cladding continue to "grow" under the erosion of water vapor, resulting in fiber breakage in the coupling area and failure. As the pictures show below, it is possible that the process of stripping the coating layer results in tiny crack on the fiber core, which will lead to a subtle but severe result during usage in the device.

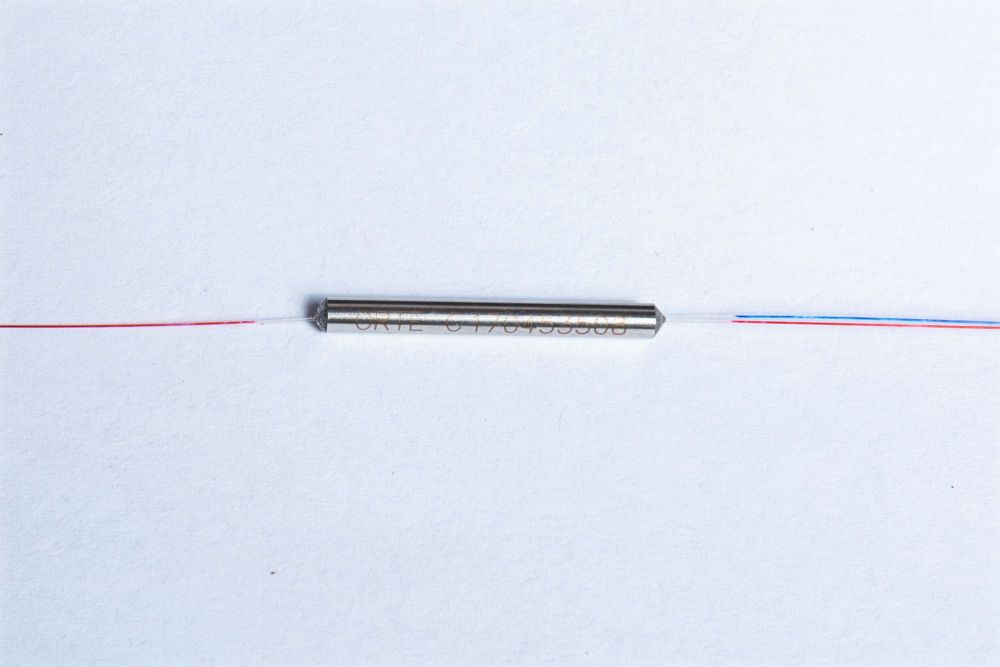

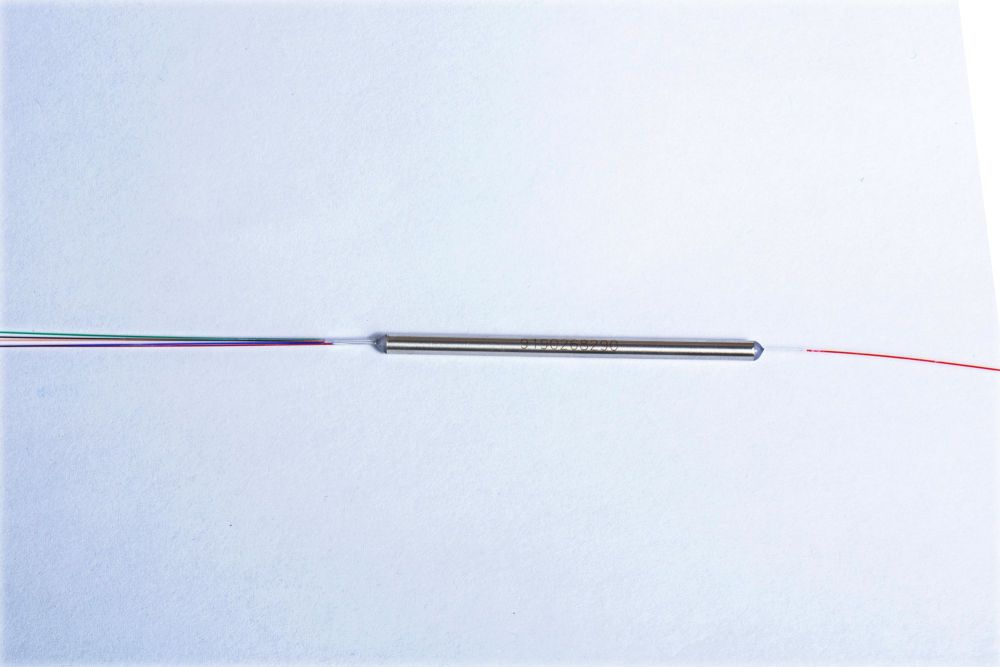

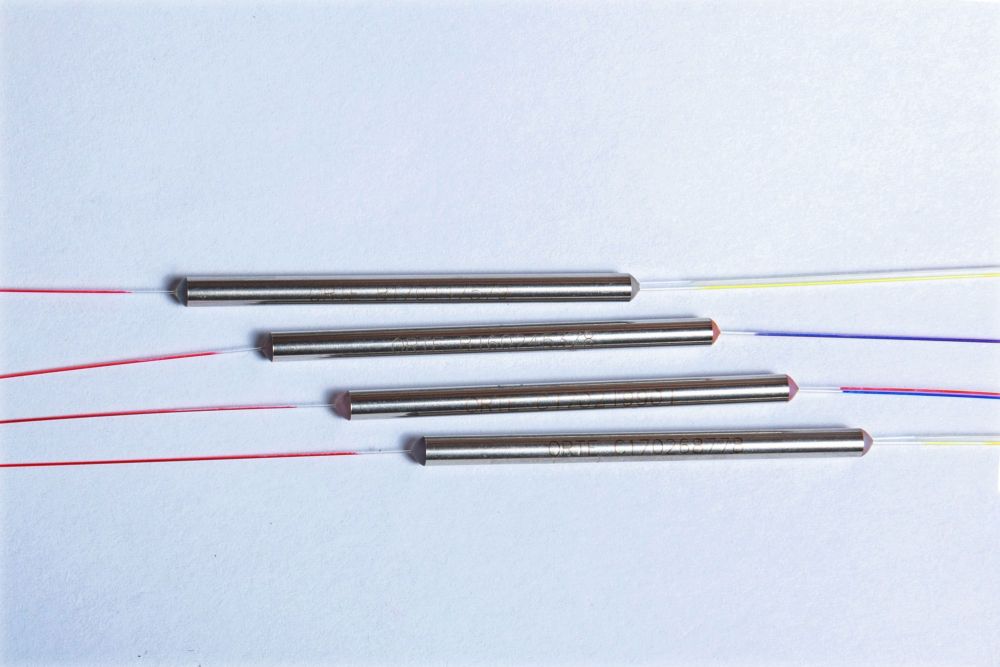

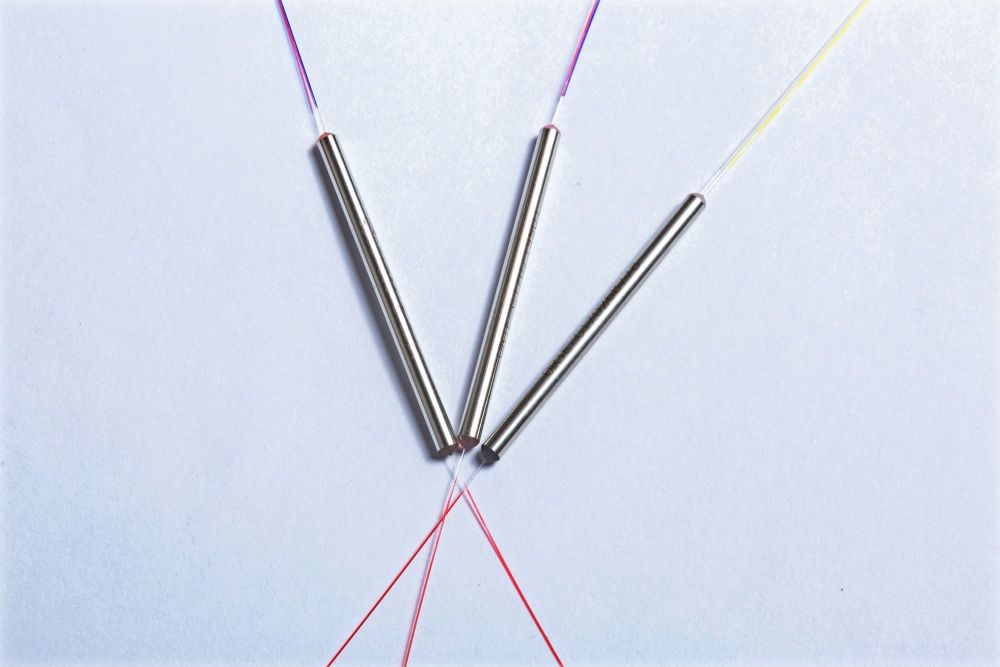

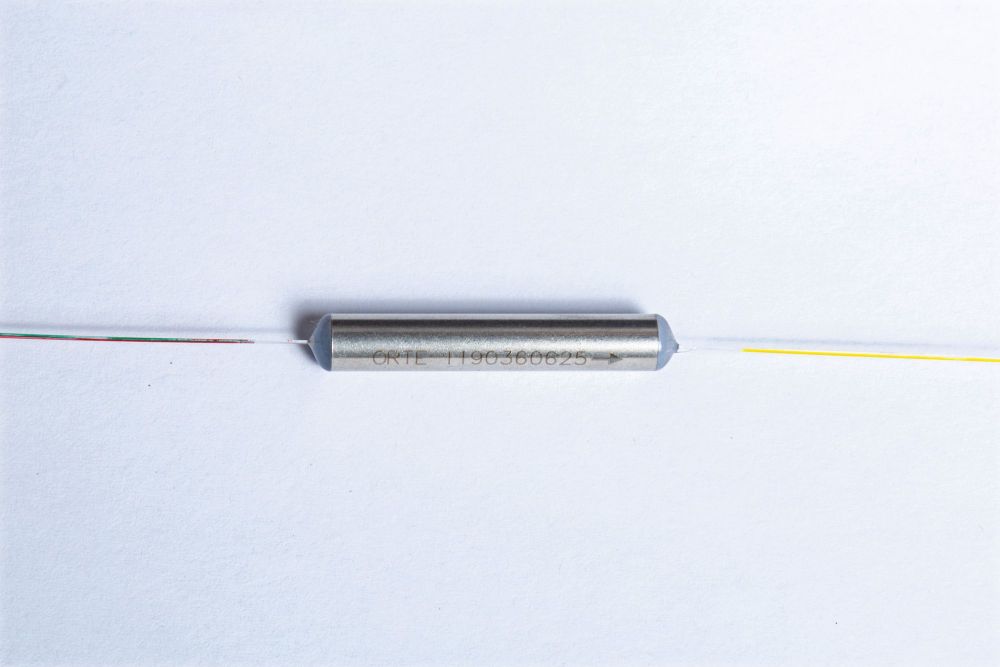

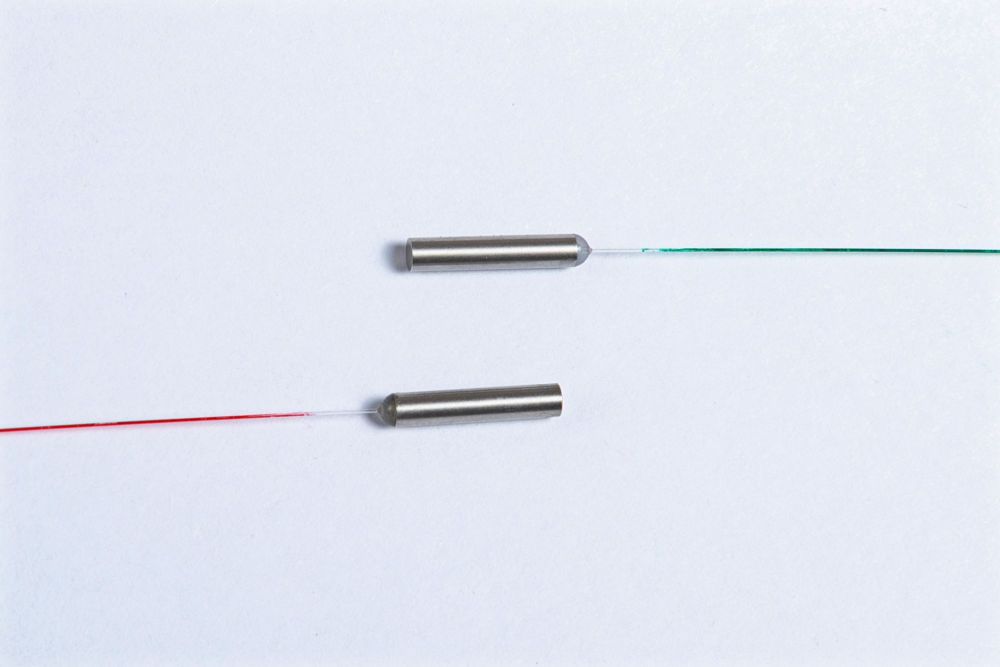

Using ORTE fiber stripping pliers to strip the coating layer, the fiber strength is significantly better than using Miller pliers. The ORTE fiber stripping pliers with independent intellectual property rights can effectively reduce the generation of micro-cracks on the surface of the fiber, with good fiber stripping consistency and non-destructive coating. Layer stripping technology is the key process technology basis for the production of high-performance optical fiber couplers. It is a totally new design , you can see in the below picture. It is not sold on the market. It is only used in ORTE photonics.